About Us

Gogreen Plus Sdn Bhd was incorporated with the Companies Commission of Malaysia (SSM) on 14th June 2017. The company immediately commenced business on 14th June 2017. The company is located in Kulai Industrial Zone, state of Johor, Malaysia.

The company currently has 50 employees. All the workers had been trained with related skills to provide quality production performance.

Our production operates 24 hours with 7 working days. APET, PP, PS cooking machines can produce 7 tons per hour and around 21 tons per day.

We strive to be an industry leader and provide our customers with the highest quality products and services with APET, PP, PS, PE, PC, OPS products, etc.

Our Vision & Mission

Our Vision We adhere to innovation and sustainable development — automation

Our Mission We are becoming the world's leading APET blister polyester materials innovators and suppliers.

Let Us Work Together to Integrate Resources and Create a Green Environmental-friendly Future

Our Team

Mr Ken Chai Min Quan 蔡明权

Founder/Director

Ken Chai is the founder of the company. He manages local and overseas export clients and explores new markets and clients. He has 10

years of experience with recycling management and its related businesses.

He frequently attends seminars on the technology and potential of biodegradable plastic, which are hosted by the Skills Development Department of the Ministry of Human Resources Malaysia.

Ken Chai is also active in the activities of major chambers of commerce including the Chinese Chamber of Commerce, the Chinese Chamber of Commerce and Industry, MPMA Malaysia Plastic Association. In addition, he has also been to China and Taiwan to conduct research and training related to environmental recycling activities.

Mr. Chin Kok Nyit

Factory & Production Manager

He acted as whole factory manager to take care of daily operations to make sure the order on time and quality of the products was fulfilling the standard operation procedure. He has 6 years’ experience in this industry and management.

Mr.Mohd Ridhuan Bin Che Darus

Administrative Executive

He acted as an administrative executive, managing daily administrative activities and human resources to fulfil the local authority council standards. He has 6 years’ experience in admin tasks in industry and management.

QAQC

Quality Control Executive/Quality Assurance

He acted as Quality Control / Quality Assurance to make sure the products quality are in good condition and was fulfilling the customer standard. He has 3 years experience in QC/QA tasks in industry.

Mr. Chai Meng Hoo

Mechanical Equipment/Electrician Maintenance Supervisor

He acted as Mechanical and Electrical maintenance technician, performing routine maintenance and administration of production line equipment to assure its proper operation. He has 5 years’ experience in this industry.

Mr. Chai Siew Mooi

Transportation Administrator

He acted as a transport executive to ensure that everyday deliveries were on time and in acceptable condition. He has 5 years’ experience in this field.

Our Warehouse & Facilities

APET/PP Sheet

Company Equipment

APET/PP Sheet

Finished Product

Company Equipment

Screening Machine and Color Sorting Machine

– the production capacity can reach 700kg per hour

Oven

Office

- The total voltage of the whole factory is 6000M

- Company land area 9 acres=392040 square feet

- Total office area is 1178 square meters

Warehouse

- Total Floor Area = 10,000 square feet

Global Export Capabilities – Supporting Your International Expansion

Chile 🇨🇱

Mexico 🇲🇽

Australia 🇦🇺

Indonesia 🇮🇩

Taiwan 🇹🇼

China 🇨🇳

Thailand🇹🇭

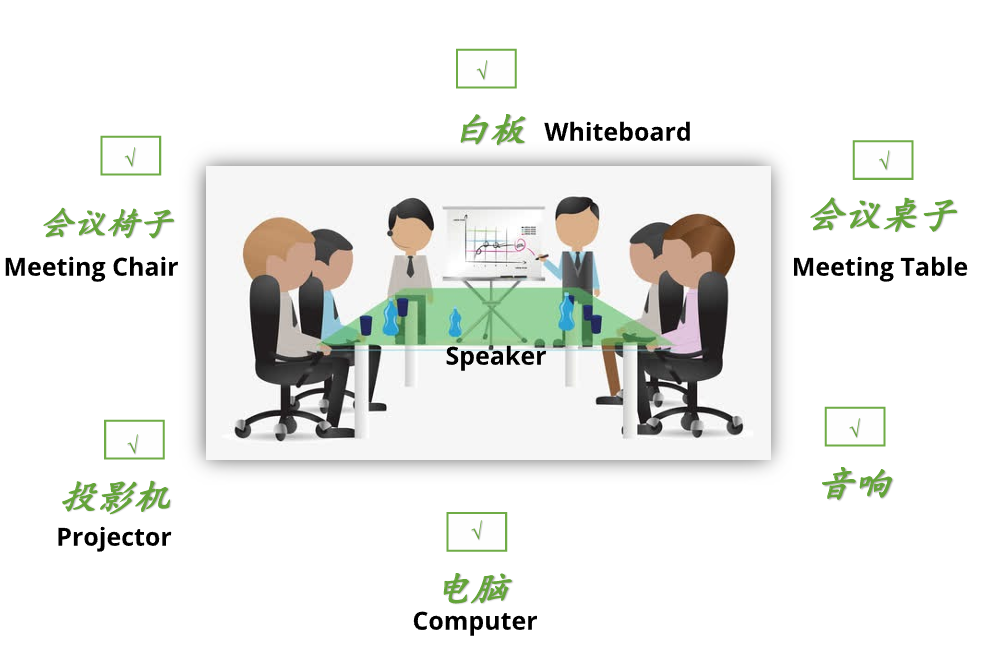

Meeting Room

- Full facilities

Tight Security

- CCTV installed throughout the factory

- 24-Hours security

- 3 security guards on morning shift

- 3 security guards on night shift

Company’s Lorries

- The company has dedicated lorry parkingarea.

- The company has restricted entry and exit times for both lorries and vehicles.

- All lorries are equipped with GPS.

Fully Automatic Crusher

- We will send the unqualified sheets to the crusher for crushing

Fully Automatic Tearing Machine

- 2 in 1

Large Fully Automatic Crushing Machine

- Break harder plastic block

Research & Development Room

- An important base for research and technological innovation

- Conduct experiments and data analysis

Loading Bay

- We have six loading bay

- Enough space for unloading

Medical Face Mask Production

• Our company also welcomes partners from related industries from local and abroad to discuss together and achieve a win-win situation for a better future

After Sales Service

There is NO absolute garbage in the world…….. only misplaced