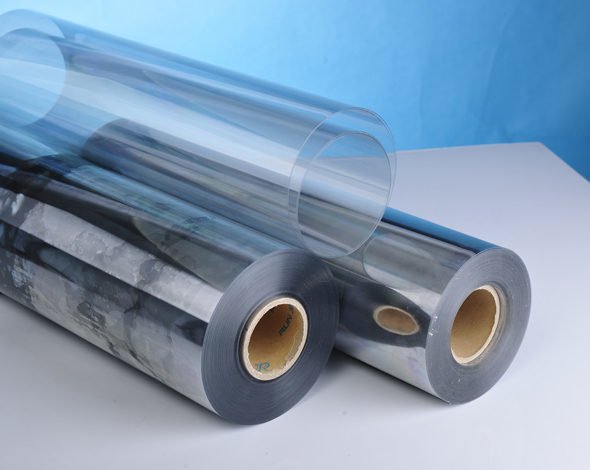

APET Sheet

Product Description

APET is a transparent plastic with a wide range of applications. The high impact resistance, excellent vacuum formability and good mechanical properties make this material ideally suited for applications in the advertising industry. Examples include displays, prize stands and poster protection.

PET Applications

PET Food Packaging Forming Tray

- Safe, lightweight, highly transparent

- High recycling value

- It can keep and preserve food

APET Folding Box

- Nice to see & good colour

- Window-type box

- Good mobility, light and convenient,

- High productivity

Food Packaging

- Food grade PET

- Excellent processing performance and compatibility

- Good production stability , high production efficiency and yield

- Low AA content , stable molecular weight and distribution

Bakery Packaging

- Food grade PET

- Low AA content , good color , stable molecular weight

- Good production stability , high production efficiency and yield

- Good fluidity and production stability , low production energy consumption , higher production efficiency

Egg Packaging

- Food grade PET

- Low AA content , stable molecular weight and distribution

- Good production stability , high production efficiency and yield

- Excellent processing performance and compatibility

Food Tray

- Food grade PET

- Excellent processing performance and compatibility

- Low AA content , stable molecular weight and distribution

- Good production stability , high production efficiency and yield

Drinking Water Bottles

- Food grade PET

- Excellent processing performance and compatibility

- Good production stability , high production efficiency and yield

- Low AA content , stable molecular weight and distribution

Bottle -grade PET chips (Food)

- Safety, light, high transparency and high recycling value. It can maintain the flavour of food and beverage

Non Bottle- grade chips (Cosmetic)

- Lower viscosity , good color , slightly low molecular weight and stable distribution

- Excellent processing performance and compatibility

- Good injection molding fluidity and high production stability